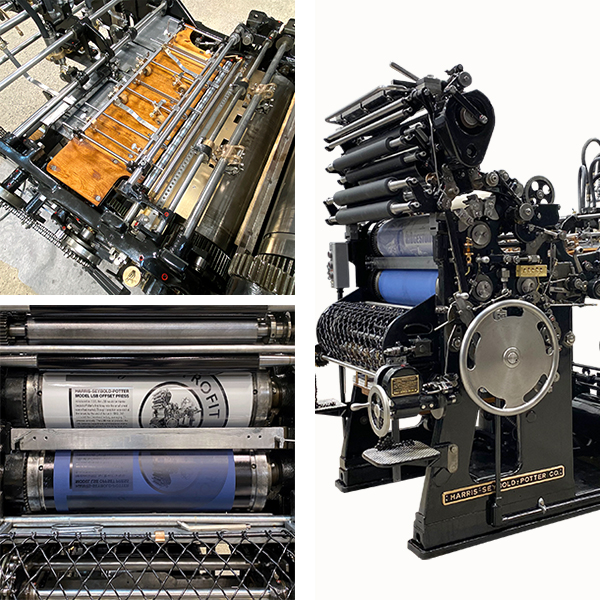

The rusty hulk sat parked inside a glass foyer of what was once home to Toronto’s Graphic Arts training school. The days of company-supported Union educational programs are, but a distant memory and this Harris LSB had to go to make room for new tenants. But the little press had lost whatever appeal it may have had and was just 4,750 pounds of obsolete machinery. Our museum (Howard Iron Works) wanted to save and restore the famous press made by an enterprising company during the height of the Great Depression.

Our museum’s LSB was built in 1935, but the first models appeared in 1933. With a maximum sheet size of 17.5” x 22.5”, this would be Harris’s first attempt at entering the rapidly growing small format offset business. As today, printers sought a cheaper and lower-cost way of printing. Letterpress was the dominant technology but Offset offered better quality, better colour, and faster speeds. Today digital manifestations are doing the exact same thing winning over users of traditional Offset. Even during the Depression years, Printers were game to try something new.

The restoration was a slow and painstaking process of re-learning and demystifying an assemblage of crude mechanical levers, cams and, often laughable by today’s standards, mechanics, for our goal was to print a job on this press to complete the renaissance. There were few challengers when the Harris LSB first came out. In England, Crabtree had built a small press, while in America, Webendorfer, with the Chief, offered the only local competition. This shows that Offset builders spent most of their resources on larger machines. Harris would build just 646 LSBs between 1933 and 1943 when the LTG superseded the model in 1945.

A 1934 advertisement for the spanking new-designed Harris LSB

After months of work, we finally ended up printing a job. A copy of a Harris 1935 advertisement was recreated and produced with a sheet size of 14” x 20”. The everyday problems and shortcomings faced by operators in the 30s were evident to us as we had to re-learn how to “copperize” the steel oscillation rollers: a long-forgotten process that, if not carried out properly would cause such lousy ink stripping that printing was impossible. Then there was the sheet feeder.

Recreation of one of Harris LSB advertisements

Unlike a modern center separation, the old Harris-HTB feeder was clunky, used “combers” to crack the pile and offered few precise adjustments. For register, the LSB didn’t have the “feed roll” infeed but rather “tumbler grippers” and front stops, timed to a “push” side guide. In order to maintain any sense of register, the feed table wheels had to be set perfectly, which was a big problem even in 1935.

The most essential tool for a pressman wasn’t a quarter-inch spanner but an oil can. The complete press was built without a single anti-friction (ball or roller) bearing. All moving parts were running in bronze or simple cast iron bearings. As typical of the times, the machine had to be oiled by hand and at regular daily intervals. To forget was a sin, and a seized part would often manifest itself at an inopportune time. In short, operating an LSB was a frustratingly difficult task, and producing quality print was an even more significant undertaking.

Letterpress was the dominant technology but Offset offered better quality, better colour, and faster speeds. Today digital manifestations are doing the exact same thing winning over users of traditional Offset. Even during the Depression years, Printers were game to try something new.

When it was time to go home, every roller had to be removed and cleaned by hand: there was no wash-up attachment for the little press. Rollers had to be replaced the next day before inking up. The molleton (cloth) dampening tray had to be filled with a water bottle as the idea of a Baldwin auto-feed jug was only starting to be installed on larger models. Too much or too little dampening solution was typical, and letterpress printers had an especially hard time learning the mystery of water and ink balance. Our print job ran well, considering we had spent plenty of hours cursing the little press.

The little offset press that went to warBut the little LSB, besides being the innovator for smaller format Offsets, had another more important role to play. In 1941, once America entered the Second World War, the LSB was used on battleships, destroyers and Quonset hut ground installations worldwide. Both the US Navy and Army Air Force came to Harris, who by war’s start had stopped building printing machines in favour of gun mounts, to request Harris produce a lightweight press in the 20” x 22.5” sheet size.

The assembly hall at Harris (Cleveland) in 1946, showing the Harris LTE

Harris LTE - the little offset press that went to war

The armed forces needed a press that could easily be moved, operated on the back of a truck or in the field, and possessed a print quality sharp enough to reproduce reconnaissance photographs. Larger presses were already utilizing the Offset process to print cartographic maps, but the idea of mobile print shops closer to the action was relatively new.

The British had already been doing this with Crabtree presses. Germans using Roland (now manroland) presses also built mobile units. The Americans had tried using Webendorfers and Multiliths. Still, neither press was ideal until Harris went to work and lobbed off over 1,000 pounds while reengineering the LSB into a special military press known as the LTE.

We are unsure how many LTEs were made by Harris as those records were never made public, but there were at least 100, and most were used in the Pacific theatre. Perhaps this explains why the only LTE known to exist is at the China Printing Museum in Beijing. The press painted an ugly green, which caught my eye when I visited a few years ago. It stands five feet tall and gives a rare glimpse into the importance of Print to the war effort.

Fully restored 1935 Harris LSB at Howard Iron Works Printing Museum

Meanwhile, our restored Harris LSB is in full bloom at Howard Iron Works, awaiting those who missed its heyday over 87 years ago!

contact the author